Design

and Manufacturing

A machine element, after design, requires to be manufactured to give it a shape

of a product. Therefore, in addition to standard design practices like, selection of proper material, ensuring proper

strength and dimension to guard against failure, a designer should have knowledge

of basic manufacturing aspects.

In this lesson, we will discuss

briefly about some of the basic manufacturing

requirements and processes.

First and foremost is assigning proper

size to a machine element from manufacturing view point. As for example, a shaft may be designed

to diameter of, say, 40 mm.

This means, the nominal diameter of the shaft is 40 mm, but the actual size will be slightly different, because it is impossible to manufacture a shaft

of exactly 40 mm diameter,

no matter what machine

is used. In case the

machine element is a mating part with another one, then dimensions of both the parts become important,

because they dictate the nature of assembly.

The allowable variation in

size for the mating parts is called

limits and the nature of assembly due to such variation in size is known as fits.

Limits

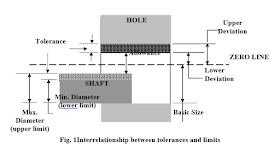

Fig. 1 explains

the terminologies used in defining tolerance and limit. The

zero line, shown in the figure, is

the basic size or the nominal size.

The definition of the terminologies is

given below. For the convenience, shaft and hole are chosen to be two mating components.