Design

and Manufacturing

A machine element, after design, requires to be manufactured to give it a shape

of a product. Therefore, in addition to standard design practices like, selection of proper material, ensuring proper

strength and dimension to guard against failure, a designer should have knowledge

of basic manufacturing aspects.

In this lesson, we will discuss

briefly about some of the basic manufacturing

requirements and processes.

First and foremost is assigning proper

size to a machine element from manufacturing view point. As for example, a shaft may be designed

to diameter of, say, 40 mm.

This means, the nominal diameter of the shaft is 40 mm, but the actual size will be slightly different, because it is impossible to manufacture a shaft

of exactly 40 mm diameter,

no matter what machine

is used. In case the

machine element is a mating part with another one, then dimensions of both the parts become important,

because they dictate the nature of assembly.

The allowable variation in

size for the mating parts is called

limits and the nature of assembly due to such variation in size is known as fits.

Limits

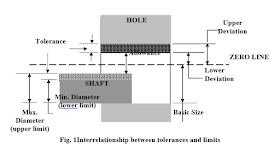

Fig. 1 explains

the terminologies used in defining tolerance and limit. The

zero line, shown in the figure, is

the basic size or the nominal size.

The definition of the terminologies is

given below. For the convenience, shaft and hole are chosen to be two mating components.

Tolerance

Tolerance is the difference between maximum and minimum dimensions of a component, ie, between upper limit and lower limit.

Depending on the type of application, the

permissible variation of dimension is set as per available

standard grades.

Allowance

It is the

difference of dimension between two mating parts.

Upper deviation

It is the difference of dimension between the maximum possible size of the component and its nominal size.

Lower deviation

Similarly, it

is the difference of dimension

between the minimum possible size of

the component and its nominal

size.

Fundamental deviation

It defines the location of the tolerance zone with respect to the

nominal size. For that matter, either of

the deviations may be considered.

Fit System

We have learnt above that a machine part

when manufactured has a specified tolerance. Therefore, when two mating parts fit with each other, the nature of fit is dependent on the limits of tolerances and fundamental deviations of the mating parts. The nature of assembly

of two mating parts is defined by

three types of fit system, Clearance Fit, Transition Fit and Interference

Fit. The fit system is shown schematically in Fig.3.

There are two ways of representing

a system. One is the hole basis and the

other is the shaft basis. In the hole basis system the dimension of the hole is

considered to be the datum, whereas, in the shaft basis system dimension

of the shaft is considered to

be the datum. The holes are normally made by

drilling, followed by reaming.

Therefore, the dimension of a hole is fixed due to the nature of the tool used.

On the contrary, the dimension of a shaft

is easily controllable by standard manufacturing processes. For this reason,

the hole basis system is much more popular than the shaft

basis

system. Here,

we shall discuss

fit system on hole basis.

Clearance Fit

In this type of fit, the shaft of largest possible

diameter can also be fitted easily even in the hole of smallest

possible diameter.

Transition Fit

In this case, there will be a clearance between

the minimum dimension of the shaft and the minimum dimension of the hole. If we look at the figure carefully,

then it

is observed that

if the shaft dimension

is maximum and

the hole dimension is minimum then an overlap

will result and this creates

a certain amount of tightness in the

fitting of the shaft inside the hole. Hence,

transition fit may have either clearance or overlap in the fit.

Interference Fit

In this case, no matter whatever may be the tolerance level in shaft and the hole, there is always a overlapping

of the matting parts. This is known

as interference fit. Interference

fit is a form of a tight fit.

Standard limit

and fit system

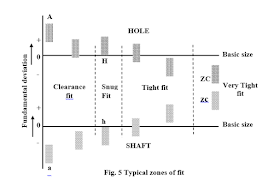

Fig. 4 shows the schematic

view of a standard limit and fit system. In this figure tolerance is denoted as IT

and it has 18 grades; greater the

number, more is the tolerance limit. The fundamental deviations for the

hole are denoted by capital letters from A and ZC, having altogether 25

divisions. Similarly, the

fundamental deviations for the shaft

is denoted by small letters from a to zc.

Here H or h is a typical case, where the fundamental deviation

is zero having an unilateral tolerance

of a specified IT grade.

Therefore in standard

limits and fit system we

find that, Standard tolerances

18 grades: IT01, IT0 and IT1-1T16

Fundamental deviations

25 types: A- ZC (For holes)

a- Zc (For shafts)

The values of standard tolerances and fundamental

deviations can be obtained

by consulting design hand book. It is to be noted

that the choice of tolerance grade is related to the type of

manufacturing process; for example, attainable tolerance grade for lapping process is lower compared to plain milling. Similarly, choice of fundamental deviation largely depends on the nature of fit, running fit or tight fit etc. The approximate zones for fit are shown in

Fig.5. Manufacturing processes involving lower tolerance grade are generally costly. Hence the designer has to keep in view the manufacturing processes to make the design effective and inexpensive.

Sample designation of limit and fit,

50H6/g5.

The designation means that the nominal size of the hole and the shaft is 50 mm. H is the nature of fit for the hole

basis system and its fundamental deviation

is zero. The tolerance grade for

making the hole is IT6. Similarly, the shaft has the fit type

g, for which the fundamental deviation

is negative, that is, its dimension

is lower than the nominal size, and tolerance grade is IT5.

Common manufacturing processes

The

types of common manufacturing processes are given below in the Fig.6

The types of shaping

processes are given below in

the Fig. 7.

Following

are the type of machining processes, shown in Fig. 8.

Various joining

processes are shown in Fig.

9.

The surface

finishing processes are given below (Fig.10).

The

non-conventional machining processes

are as follows (Fig.11),

No comments:

Post a Comment