Lines

Lines is one important aspect of technical drawing. Lines are always used to construct meaningful drawings. Various types of lines are used to construct drawing, each line used in some specific sense. Lines are drawn following standard conventions mentioned in BIS (SP46:2003). A line may be curved, straight, continuous, segmented. It may be drawn as thin or thick. A few basic types of lines widely used in drawings are shown in Table 1.

Lines is one important aspect of technical drawing. Lines are always used to construct meaningful drawings. Various types of lines are used to construct drawing, each line used in some specific sense. Lines are drawn following standard conventions mentioned in BIS (SP46:2003). A line may be curved, straight, continuous, segmented. It may be drawn as thin or thick. A few basic types of lines widely used in drawings are shown in Table 1.

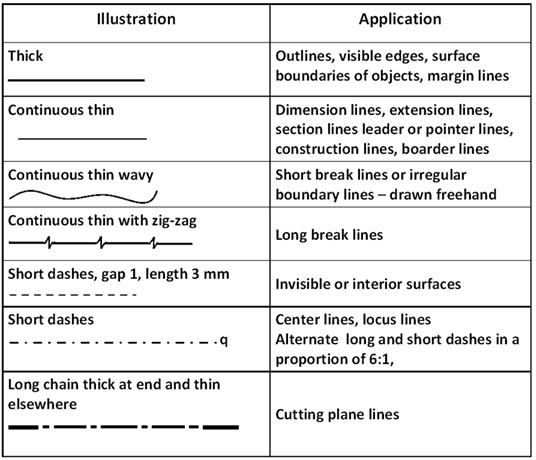

Table 1. Types of letters used in engineering drawing.

Line Strokes

Line strokes refer to the directions of drawing straight and curved lines. The standards for lines is given in BIS : SP-46, 2003

Vertical and inclined lines are drawn from top to bottom, horizontal lines are drawn from left to right. Curved lines are drawn from left to right or top to bottom. The direction of strokes are illustrated in figure 1.

Line strokes refer to the directions of drawing straight and curved lines. The standards for lines is given in BIS : SP-46, 2003

Vertical and inclined lines are drawn from top to bottom, horizontal lines are drawn from left to right. Curved lines are drawn from left to right or top to bottom. The direction of strokes are illustrated in figure 1.

Conventions used in lines

· 1. International systems of units (SI) – which is based on the meter.

· 2. Millimeter (mm) - The common SI unit of measure on engineering drawing.

· 3. Individual identification of linear units is not required if all

dimensions on a drawing are in the same unit (mm).

· 4. The drawing should contain a note: ALL DIMENSIONS ARE IN MM. (Bottom

left corner outside the title box)

5.Typical figures showing various lines

used in the construction of engineering drawing is shown in figure 2.

A typical use of various lines in an

engineering drawing is shown in figure below:

Dimensioning

The size and other details of the object essential for its construction and function, using lines, numerals, symbols, notes, etc are required to be indicated in a drawing by proper dimensioning. These dimensions indicated should be those that are essential for the production, inspection and functioning of the object and should be mistaken as those that are required to make the drawing of an object. The dimensions are written either above the dimension lines or inserted at the middle by breaking the dimension lines.

The size and other details of the object essential for its construction and function, using lines, numerals, symbols, notes, etc are required to be indicated in a drawing by proper dimensioning. These dimensions indicated should be those that are essential for the production, inspection and functioning of the object and should be mistaken as those that are required to make the drawing of an object. The dimensions are written either above the dimension lines or inserted at the middle by breaking the dimension lines.

Normally two types of dimensioning

system exist. i.e. Aligned system and the unidirectional system.These are shown

in figure 3.

In the aligned system the dimensions

are placed perpendicular to the dimension line in such a way that it may be

read from bottom edge or right hand edge of the drawing sheet. The horizontal

and inclined dimension can be read from the bottom where as all the vertical

dimensions can be read from the right hand side of the drawing sheet.

In the unidirectional system, the dimensions are so oriented such that they can be read from the bottom of the drawing.

In the unidirectional system, the dimensions are so oriented such that they can be read from the bottom of the drawing.

Rules to be followed for dimensioning.

Refer figure 4.

1. Each feature is dimensioned and positioned only once.

· 2.Each feature is dimensioned and positioned where its shape shows.

· 3Size dimensions – give the size of the component.

· 4. Every solid has three dimensions, each of the geometric shapes making up

the object must have its height, width, and depth indicated in the

dimensioning.

Dimensioning consists of the

following:

·

A thin, solid line that shows the extent and direction of a

dimension. Dimension lines are broken for insertion of the dimension

numbers

·

Should be placed at least 10 mm away from the outline and all

·

other parallel dimensions should be at least 6 mm apart, or more, if

space permits

The important elements of

dimensioning consists of extension lines, leader line, arrows and dimensions.

Extension line – a thin,

solid line perpendicular to a dimension line, indicating which feature is

associated with the dimension. There should be a visible gap of 1.5 mm between

the feature’s corners and the end of the extension line.Figure 5 shows

extension lines.

Leader line

A thin, solid line used to indicate the feature with which a dimension, note, or symbol is associated. Generally this is a straight line drawn at an angle that is neither horizontal nor vertical. Leader line is terminated with an arrow touching the part or detail. On the end opposite the arrow, the leader line will have a short, horizontal shoulder. Text is extended from this shoulder such that the text height is centered with the shoulder line

Leader line

A thin, solid line used to indicate the feature with which a dimension, note, or symbol is associated. Generally this is a straight line drawn at an angle that is neither horizontal nor vertical. Leader line is terminated with an arrow touching the part or detail. On the end opposite the arrow, the leader line will have a short, horizontal shoulder. Text is extended from this shoulder such that the text height is centered with the shoulder line

·

Arrows – 3 mm wide and should be 1/3rd as wide as they are long -

symbols placed at the end of dimension lines to show the limits of the

dimension. Arrows are uniform in size and style, regardless of the size

of the drawing.Various types of arrows used for dimensioning is shown in figure

6.

Dimensioning of angles: The normal convention for dimensioning of angles

are illustrated

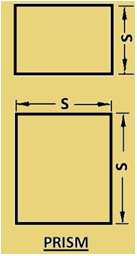

Few examples during dimensioning of

solids are shown below:

·

Prism – This is the most common shape and requires

three dimensions. Two dimensions shown on the principal view and

the third dimension on the other view.

·

Cylinder – Cylinder is the second most common shape. It requires

two dimensions: diameter and length, both shown preferably on the

rectangular view.

·

Cone – requires two dimensions – diameter of the base and altitude

on the same view and length. Both shown on the rectangular view is preferred.

·

Right pyramids – requires three dimensions – dimensions of the

base and altitude.

·

Spheres – requires only one dimension. i.e. diameter.

However in case of extra features, those dimensions are required to be

provided.

RULES OF DIMENSIONING

1. Between any two

extension lines, there must be one and only one dimension line bearing one

dimension.

2. As far as possible,

all the dimensions should be placed outside the views. Inside dimensions are

preferred only if they are clearer and more easily readable.

3. All the dimensions

on a drawing must be shown using either Aligned System or Unidirectional

System. In no case should, the two systems be mixed on the same drawing.

4. The same unit of

length should be used for all the dimensions on a drawing. The unit should not

be written after each dimension, but a note mentioning the unit should be

placed below the drawing.

5. Dimension lines

should not cross each other. Dimension lines should also not cross any other

lines of the object.

6. All dimensions must

be given.

7. Each dimension

should be given only once. No dimension should be redundant.

8. Do not use an

outline or a centre line as a dimension line. A centre line may be extended to

serve as an extension line.

9. Avoid dimensioning

hidden lines.

10. For dimensions in

series, adopt any one of the following ways.

i.

Chain dimensioning (Continuous dimensioning) All the dimensions are

aligned in such a way that an arrowhead of one dimension touches tip-to-tip the

arrowhead of the adjacent dimension. The overall dimension is placed outside

the other smaller dimensions.

ii.

Parallel dimensioning (Progressive dimensioning) All the dimensions are

shown from a common reference line. Obviously, all these dimensions share a

common extension line. This method is adopted when dimensions have to be

established from a particular datum surface

iii.

Combined dimensioning. When both the methods, i.e., chain

dimensioning and parallel dimensioning are used on the same drawing, the method

of dimensioning is called combined dimensioning.

Great blog. All posts have something to learn. Your work is very good and i appreciate you and hopping for some more informative posts. Selling surplus automation parts NZ

ReplyDeleteCadforyou: Lines And Dimensions >>>>> Download Now

ReplyDelete>>>>> Download Full

Cadforyou: Lines And Dimensions >>>>> Download LINK

>>>>> Download Now

Cadforyou: Lines And Dimensions >>>>> Download Full

>>>>> Download LINK kh